MATERIAL

Property

CR (Chloroprene Rubber)

CR is used in variable transportation field such as automotive, railroad. It has superior resistance to ammonia, freon, acid base, flame, weather, ozone, sunlight, oxygen.

CR Service Temperatures

From -40 °C to +100 °C

Chemical Resistance

- Mineral oil(eg.ASTM oil No.1)

- Silicone oil and grease

- Water and water solvent at low temperature

- Refrigerants

- Ammonia(NH3)

- Carbon dioxide(CO2)

- Improved ozone resistance, weather resistance, aging resistance compared with NBR

Not Compatible With

- Aromatic hydrocarbons

- Chlorinated hydrocarbons

- Polar solvents : ketone, acetone, ether, ester

- Mineral oils : ASTM oil No.2 and No.3

- Aliphatic Hydrocarbons : propane, butane, fuel

NBR (Acrylonitrile-Butadiene Rubber)

NBR has higher mechanical property and abrasion resistance than other elastomer.

NBR have lower weather resistance and ozone resistance.

It is used in wide spread fields such as hydraulic machines, automotive, ships, Aeronautical fuel system, construction equipments. It has superior resistance to hydraulic oil, water, alcohol, silicone, grease, hydrocarbon fuel.

NBR Service Temperatures

From -40 °C to +100 °C

Chemical Resistance

- Aliphatic Hydrocarbons : propane, butane, petroleum oil, vegetable oils, mineral oil and greases, diesel fuel.

- HFA, HFB, HFC

- Diluted base, acid, alkali in low temperature

- Superior water resistance(up to 100 °C)

Not Compatible With

- Aromatic hydrocarbons

- Fuel incl. aromatic hydrocarbons

- Chlorinated hydrocarbons as trichloroethylene

- Polar solvents : ketone, acetone, acetic acid, ethylene ester

- Strong Acids

- Brake Fluids with glycol base

- Ozone, weather and atmospheric aging

HNBR (Hydrogenated Nitrile Rubber)

HNBR exhibits satisfactory compatibility with automotive fuel system, hydrocarbon, diesel fuel, refrigerants R-11, R-12, R-134a, antioxidants, hydraulic oil, oil additive, ozone, diluted base and acid.

It has good tensile strength.

HNBR Service Temperatures

From -40 °C to +150 °C

Chemical Resistance

- Aliphatic Hydrocarbons : propane, butane, petroleum oil, vegetable oils, mineral oil and greases.

- HFA, HFB, HFC fluids

- Hot water and steam up to 149 °C

- Diluted base, acid, alkali in low temperature

- Superior weather resistance and ozone resistance

Not Compatible With

- Trichloroethylene, chlorinated hydrocarbons

- Polar solvents : ketone ester

- Strong Acids

EPDM, EPM (Ethylene Propylene Diene Monomer Rubber)

glycol. EPDM exhibits satisfactory compatibility with steam, hot water, ozone, sun light, hydraulic oil, automotive brake/cooling system, acetone, ketone, polar solvents as MEK, silicone oil/grease, diluted acid Alkali, brake oil.

It has good tensile strength, compression set.

EPDM Service Temperatures

From -50 °C to +125 °C

Chemical Resistance

- Hot water and steam up to 149 °C

- Brake fluids with glycol base

- Organic and inorganic acids

- Cleaning agent, soda and potassium alkalis

- Hydraulic fluids based on phosphate ester(HFD-R)

- Silicone oil and grease

Not Compatible With

- Mineral oil products : oil, greases, fuels

- Gasoline, kerosene

- Aromatic and Aliphatic hydrocarbons

- Halogenated solvents

- Concentrated acid

SILICONE (VMQ, PVMQ)

Whereas has superior weather resistance, ozone resistance, insulation, heat resistance, low temperature strength with physiologically neutral properties.

VMQ Service Temperatures

From -60 °C to +220 °C

Chemical Resistance

- Engine and transmission oil(ASTM oil No.1)

- Vegetable and animal oil and grease

- Brake oil(non-petroleum base)

- Fire-resistant hydraulic fluid : HFD-R, HFD-S

- Chlorinated aromatic hydrocarbon incl. flame resistance, refrigerants for transformer

- Water up to +100 °C

- Diluted salt solutions

- Superior ozone resistance, weather resistance, aging resistance

Not Compatible With

- Steam more than 120°C

- Acids and alkalis

- Chlorinated hydrocarbon : trichlorethylene

- Mineral oil

- Aliphatic hydrocarbons : propane, butane, fuel

- Hydrocarbon based fuel

- Aromatic hydrocarbons

Fluorosilicone (FVMQ)

Whereas has superior weather resistance, ozone resistance, insulation, heat resistance, low temperature strength with physiologically neutral properties.

FVMQ offers improved fuel and mineral oil resistance, but poorer hot air resistance than standard VMQ.

FVMQ Service Temperatures

From -60 °C to +175 °C

Chemical Resistance

- Engine and transmission oil(ASTM oil No.1)

- Vegetable and animal oil and grease

- Brake oil(non-petroleum base)

- Fire-resistant hydraulic fluid : HFD-R, HFD-S

- Chlorinated aromatic hydrocarbon incl. flame resistance, refrigerants for transformer

- Water up to +100 °C

- Diluted salt solutions

- Superior ozone resistance, weather resistance, aging resistance

Not Compatible With

- Steam more than 120°C

- Acids and alkalis

- Chlorinated hydrocarbon : trichlorethylene

- Mineral oil

- Aliphatic hydrocarbons : propane, butane, fuel

- Hydrocarbon based fuel

- Aromatic hydrocarbons

FKM, FPM (Viton)

Fluoroelastomers are more expensive than neoprene or nitrile rubber elastomers partly because they provide additional heat and chemical resistance.

FKMs can be divided into different classes on the basis of either their chemical composition, their fluorine content or their crosslinking mechanism.

Chemical Name

Fluoroelastomer, Fluorinated Rubber, Fluorocarbon Rubber, Fluorine Rubber.

Brand Name

Viton(DuPont-Dow Elastomer), Fluorel(3M), Dyneon(Dyneon Co.), Tecnoflon(Ausimont Corp.)

FKM Service Temperatures

From -25 °C to +250 °C

- Caution by varying duty more than 200 °C

- Minimum usable temperature varied by Vitons .

Chemical Resistance

- Second superior chemical resistance and heat resistance to Perfluoroelastomer in commercialized brands.

- Superior resistance to oil, fuel, lubricant, aliphatic, aromatic hydrocarbons, hydrocarbons.

Not Compatible With

- Oxygenated solvents, ester, ether, ketone, some amine, chlorosulfonic-acid.

FFKM, FFPM (KALEZ, PERLAST)

As all of the bonds on the backbone are carbon-fluorine then FFKM materials offer the ultimate thermo-chemical resistance shown by the good long-term high temperature compression-set resistance.

This is demonstrated by the good longterm, high-temperature, compressionset resistance.

Chemical resistance is second to none, with good performance in a broad variety of harsh environments:hot amines, steam, solvents, hydrocarbons etc.

Traditionally, FFKM polymers have offered limited resistance to low temperatures, however, new polymer chemistry now offers FFKM grades capable of sealing at temperatures down to -40°C.

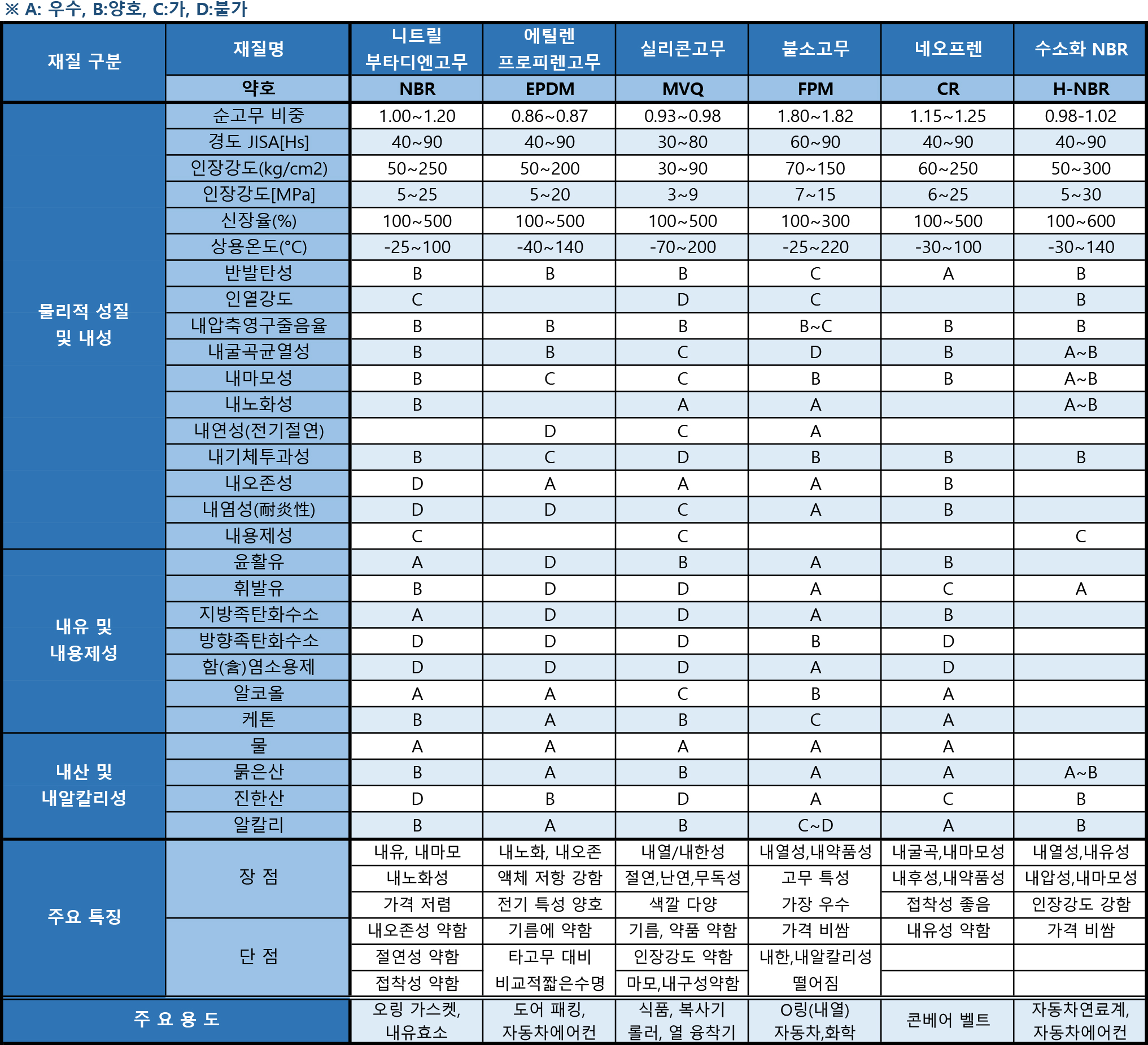

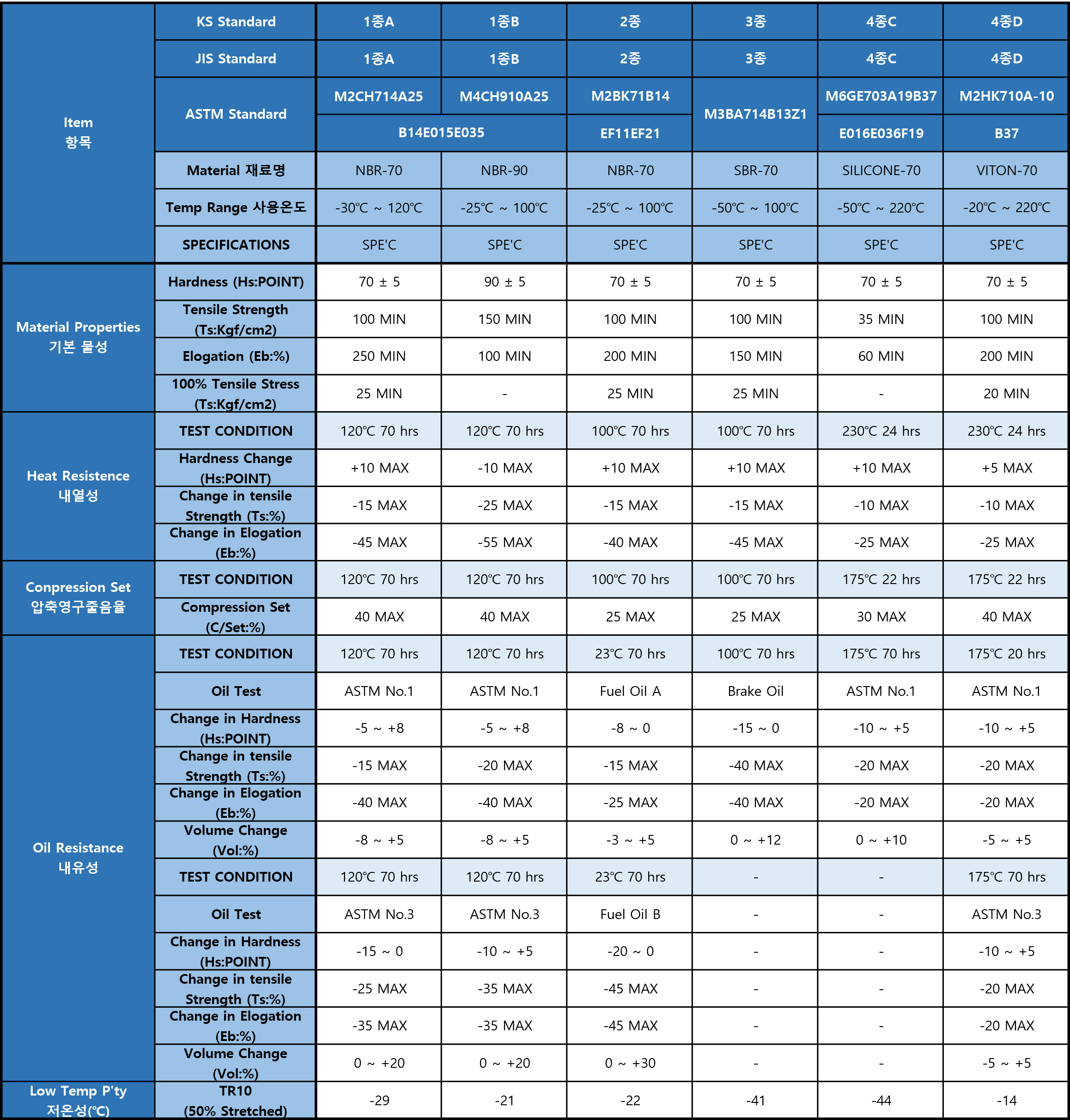

O-Ring Rubber Material Properties

Rubber Material Properties